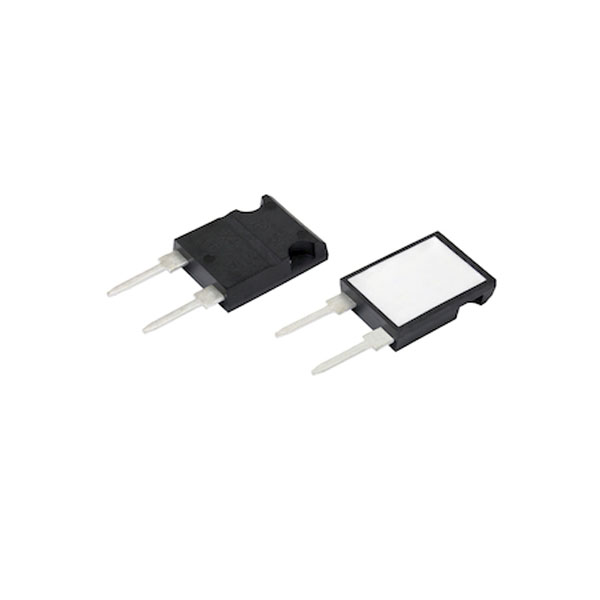

Highly Trustable and Self-developed TO-247AC SiC Diode

Advantages of YUNYI's TO-247AC SiC Diode:

1. Extremely low failure rate in different weathers and areas

2. Competitive cost with high-level quality.

3. High production efficiency with short lead time.

4. Diode's functions are optimized, benefiting from the scientific protection on PN junction.

5. Approved by the standards of IATF16949,ISO14001, ISO 9001:2005, OHSAS18001, VDA6.3, etc.

Process of Chip Production:

1. Mechanically Printing(Super-precise automatic wafer printing)

2. Automatic First-etching (Automatic Etching Equipment,CPK>1.67)

3. Automatic Polarity Test(Precise Polarity Test)

4. Automatic Assembly (Self-developed Automatic Precise Assembly)

5. Soldering (Protection with Mixture of Nitrogen & Hydrogen Vacuum Soldering )

6. Automatic Second-etching (Automatic Second-etching with Ultra-pure Water)

7. Automatic Gluing (Uniform Gluing & Precise Calculation are Realized by Automatic Precise Gluing Equipment)

8. Automatic Thermal Test (Automatic Selection by Thermal Tester)

9. Automatic Test(Multifunctional Tester)

Parameters of products:

| Part Number | Package | VRWM V |

IO A |

IFZM A |

IR μa |

VF V |

| Z3D20065H | TO-247AC | 650 | 20 | 170 | 50(1.5 typical) | 1.7(1.45 typical) |

| ZICR201200W | TO-247AC | 1200 | 20 | 173 | 50 | 1.7 |

| Z3D30065H | TO-247AC | 650 | 30 | 255 | 140(4 typical) | 1.7(1.4 typical) |

| Z4D10120H | TO-247AC | 1200 | 10 | 105 | 200(30 typical) | 1.8(1.5 typical) |

| Z4D20120H | TO-247AC | 1200 | 20 | 162 | 200(35 typical) | 1.8(1.5 typical) |

| Z4D15120H | TO-247AC | 1200 | 15 | 100 | 200(35 typical) | 1.8(1.5 typical) |

| ZICRZ50650WT | TO-247AD | 650 | 50 | 400 | 500 | 1.7 |

| ZICR20600WT | TO-247AD | 600 | 20 | 40 | 150 | 1.7 |

| ZICR20650WT | TO-247AD | 650 | 20 | 40 | 150 | 1.7 |

| ZICR40600WT | TO-247AD | 600 | 40 | 70 | 300 | 1.7 |

| ZICR40650WT | TO-247AD | 650 | 40 | 70 | 300 | 1.7 |

| ZICR201200WT-2 | TO-247AD | 1200 | 20 | 50 | 200 | 1.8 |

| ZICR201200WT-4 | TO-247AD | 1200 | 20 | 70 | 250 | 1.8 |

| ZICR201200WT | TO-247AD | 1200 | 20 | 70 | 250 | 1.8 |

| Z3D10065D1 | TO-247AD | 650 | 10 | 115 | 40(0.7 typical) | 1.7(1.45 typical) |

| Z3D20065D | TO-247AD | 650 | 20 | 115(per leg) | 40(0.7 typical)(per leg) | 1.7(1.45 typical)(per leg) |

| Z3D30065D1 | TO-247AD | 650 | 30 | 255 | 140(4 typical) | 1.7(1.4 typical) |

| Z4D20120D | TO-247AD | 1200 | 20 | 105(per leg) | 200(30 typical)(per leg) | 1.8(1.5 typical)(per leg) |

| Z4D40120D | TO-247AD | 1200 | 40 | 162(per leg) | 200(35 typical)(per leg) | 1.8(1.5 typical)(per leg) |

| Z4D15120D | TO-247AD | 1200 | 15 | 64(per leg) | 200(35 typical)(per leg) | 1.8(1.6 typical)(per leg) |

| Z3D35065D1 | TO-247AD | 650 | 35 | 270 | 80(0.6 typical) | 1.7(1.5 typical) |

| Z3D40065D | TO-247AD | 650 | 40 | 170(per leg) | 50(1.5 typical)(per leg) | 1.7(1.45 typical)(per leg) |

| Z4D10120D | TO-247AD | 1200 | 10 | 46(per leg) | 200(20 typical)(per leg) | 1.8(1.65 typical)(per leg) |

| Z3D16065D | TO-247AD | 650 | 16 | 69 | 20(0.5 typical) | 1.5(1.35 typical) |

| Z4D30120D | TO-247AD | 1200 | 30 | 100(per leg) | 200(35 typical) | 1.8(1.55 typical) |

| Z3D30065D | TO-247AD | 650 | 31 | 162(per leg) | 25(0.5 typical) | 1.7(1.5 typical)(per leg) |